Your basket is currently empty!

Unlike many of Egbert Taylor’s long timers, I’m relatively new. Well, six years in – but still, compared to some people here I’m a newbie.

I joined the business from Doves Farm Foods in Hungerford. It was great, but not when you’re commuting 210 miles each day.

It wasn’t always that way, though. I moved from Kidderminster to Oxford, which is where I got the job – but then moved back to Kidderminster, where I live now, and kept the role. In my first year I drove 92,000 miles! Now, my commute to Oak Park is seven minutes – door to door – which is much better (for me and my car).

I’ll generally get to work somewhere between 7.30 – 8am. It’s particularly busy at the moment as a result of the growing supply chain issues around the world. 80 per cent of EU steel mills source their plate steel from either Russian or Ukrainian firms, so the sanctions on Russia and the bombing of Ukrainian steel mills means that there is a vast shortage of supply throughout Europe and the UK. This, coupled with huge rises in energy costs, has resulted in price increases across the board.

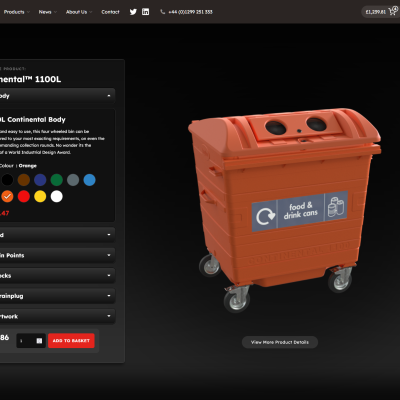

The same applies to the polymer we rely on to make our plastic lids. The fact is material shortages provide an added challenge for all manufacturers. However, we have a number of contingency plans in place and our production levels remain unaffected. Importantly, we’re still keeping our customers happy.

Many of our suppliers are now having to trade further afield just to accommodate businesses, which, like us, are dependent on raw materials. This is just another challenge that we must overcome following the events in recent years: Brexit, Covid and now a war. China has recently gone back into lockdown because of Covid, which is affecting supply to the UK and the rest of the world. These issues have masked the impact of Brexit on the UK economy and I believe that we are yet to see the full effect of Brexit. However, the above is unsustainable and things can only get better moving forward for everyone.

My day-to-day job involves a bit of everything. I manage all inventory on site. I also manage all purchases – from stationery, IT, raw materials for production through to gas and electric contracts. I negotiate pricing, SLAs, KPIs and contracts with suppliers. In recent years, we have helped our suppliers’ source raw materials because of global supply shortage. Keeping on top of this can be like spinning plates, and in a climate where material costs are increasing on a daily basis, it adds yet another challenge. After all, it’s important that customer’s get accurate pricing at all times. Thankfully, I’ve implemented a system that provides live prices at any given time, the result of which protects our customers and, of course, Egbert Taylor.

By the end of the day, I’m quite tired. Now the evenings are getting lighter I’m able to spend an hour or two in the garden. Or, if it’s too dark (or cold), I’ll go for a game of snooker. My hobbies are much more sedate these days. I used to ride motorbikes, but after a serious collision with a car who just pulled out, which resulted in me sliding under it, I’ve hung up my motorbike boots.

Still, Egbert Taylor keeps me busy. The people I work with are great, we have a strong team and everyone at here supports each other.